Metallurgy, Heavy Machinary and Hydropower Intro

Metallurgy

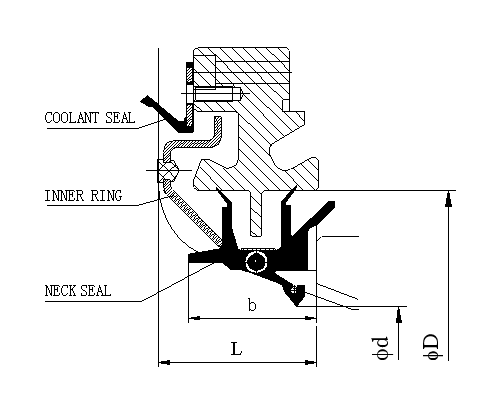

Sealing products are widely used in the metallurgical industry. Rubber and plastic products such as Neck Seals, Coolant Seals, Channel Seal and Rolling Mill Seals are silently protecting mechanical operation and environmental safety. In SINOMACH Sealing, we have provided these products for our overseas customers for the past nearly 20 years.

Neck Seal

Coolant Seal

Heavy Machinery

In the field of heavy machinery seals, SINOMACH Sealing has broken through a number of key core technologies for large-scale rubber seals in high-end equipment, and the achievements have been applied in high-end equipment matching in the heavy machinery industry, ensuring the efficient, high-quality, and reliable operation of the main engine, reducing major environmental or safety accidents, promoting the transformation and upgrading of the equipment manufacturing industry, and overcoming major obstacles from large to strong.

The sealing technology and products of large-scale shield tunneling have reached the world leading class. Promoted and applied to well-known enterprises such as China Railway Tunnel for main drive sealing and articulated sealing. The shield tunneling equipment used in railway tunnels is truly a "sealed barrier"

The control accuracy and quality stability of large-scale forging hydraulic presses cannot be achieved without the control level of hydraulic cylinders. The role of hydraulic cylinder seals is crucial. After the sealing products were installed, the equipment operates normally under a working pressure of 63MPa (maximum 90MPa), and the design requirements for a service life of more than 2 years meet the world leading class.

The research and development, design, production, and installation of specialized seals for 80000 ton forging presses, which were rapidly developed by SINOMACH Sealing, have ensured the smooth implementation of major national projects. At present, the oil cylinder sealing ring of the 80000 ton forging press has been in use for more than 5 years, with reliable quality and zero equipment failure rate caused by sealing failure, reaching the international leading level.

Hydropower

SINOMACH Sealing has proposed an integrated equipment and process technology for rotary additive forming of large and ultra large integral seals and precision turning of low modulus elastomers. It has independently developed multiple types and series of CNC machining equipment.

Integrated one-time molding Φ 13.3-meter sealing product, the world's first, has been in safe service for nearly 10 years in the 700MW hydroelectric generator set of Three Gorges Dam. It has also been applied to 800MW hydroelectric units in Xiangjiaba Dam. It ensures the safe, efficient, and stable service of national super engineering, major national heavy equipment, and other equipment. Before the renovation of the generator of Yangtze Power, 500 tons of hydraulic oil leaked into the Yangtze River in a year, greatly affecting the water consumption of urban residents downstream of Gezhouba Dam. And so far there has been no sealing leakage failure after the application of the new designed seal.