Semiconductor Industry

Production Abilit

To better serve customers in the semiconductor industry, SINOMACH Sealing has established a specialized production workshop with a 10,000-level cleanliness production area of and a 100-level cleanliness cleaning and packaging area that can customize personalized sealing products based on customer needs.

R&D Capabilit

In terms of research and development equipment, SINOMACH Sealing has the only national rubber and plastic seal research platform in China, with more than 3500m2 of the central laboratory space for comprehensive evaluation of sealing materials and sealing products, including bench testing, full condition aging testing and life assessment capabilities.

Talent Team

In terms of R&D team building, SINOMACH Sealing has 10 professor senior engineers and 115 engineers with professional titles at all levels. Establish a technical team dedicated to serving the semiconductor industry, providing professional technical support in material selection, size selection, manufacturing, after-sales services and other links

Characteristic Products

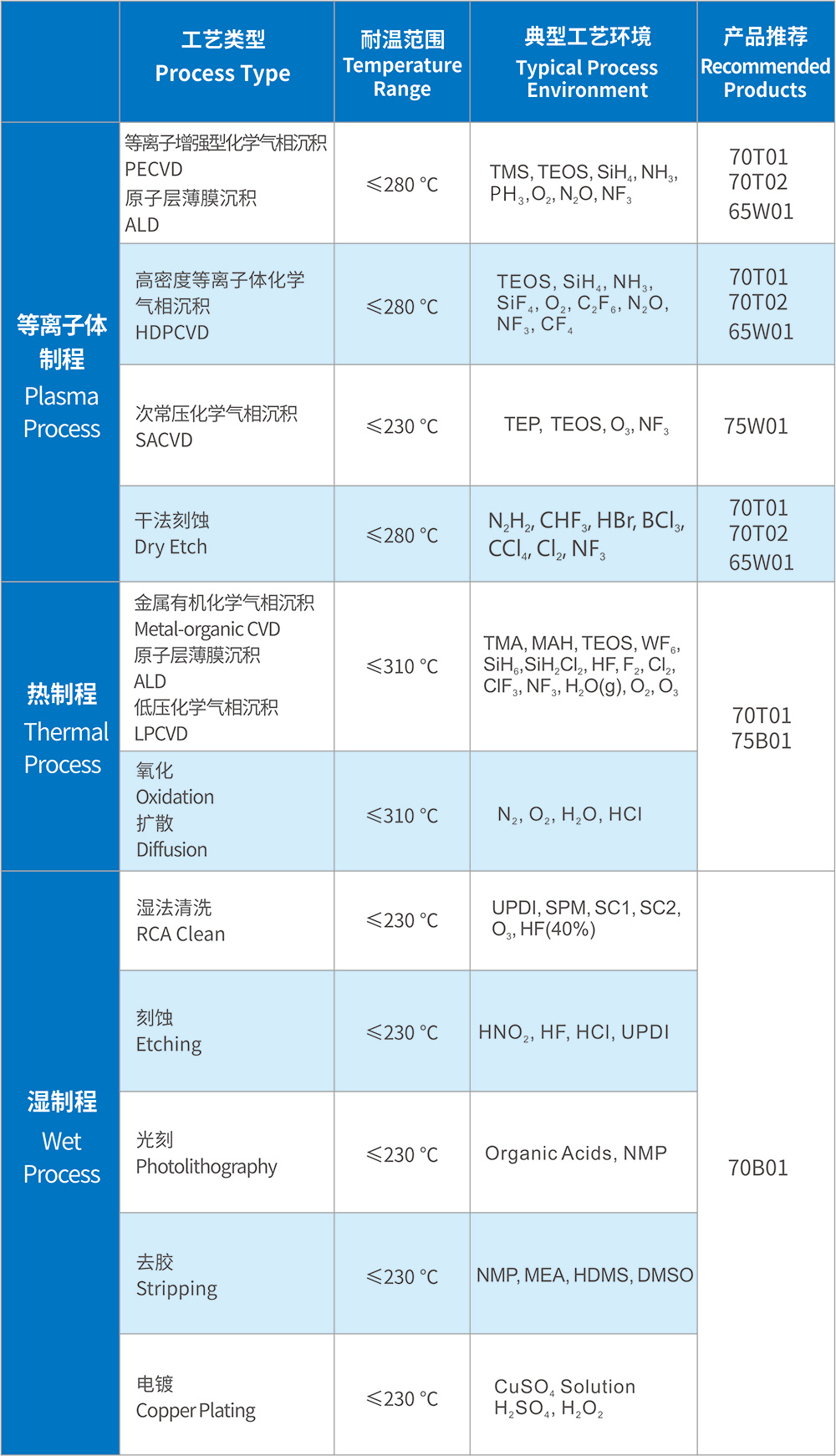

The sealing products of SINOMACH Sealing have superior plasma resistance, high temperature resistance, acid and alkali corrosion resistance, and are widely used in the three major processes of chip manufacturing. Combined with the different characteristics of etching, deposition, chemical-mechanical polishing, thermal treatment, cleaning and other processes, the corresponding sealing solutions are provided.

For etching, deposition and other processes that requiring plasma precipitation and chemical corrosion resistance, models 70T01, 70T02, 75W01 and others are recommended. For deposition, oxidation, heat treatment and other processes requiring high temperature resistance, 70T01, 5B01 and other models are recommended. Models such as the 70B01 are recommended for other wet process technologies. (See the product brochure for details)

Guangzhou State secret seal technology Co., LTD

Online message

Contact Us