OIL AND GAS INDUSTRY

Through various innovative technologies, SINOMACH Seal helps all kinds of oil and gas equipment on land and offshore to operate stably, efficiently and sustainably.

With cutting-edge material formulations and excellent manufacturing capabilities, we can provide more customized sealing solutions, rich and in-depth products for you, and help contribute the sustainable development for the industry. We're a sealing partner for oil and gas equipment, helping you solve tough problems, seize opportunities that matter, and make a difference.

01

Sealing solutions

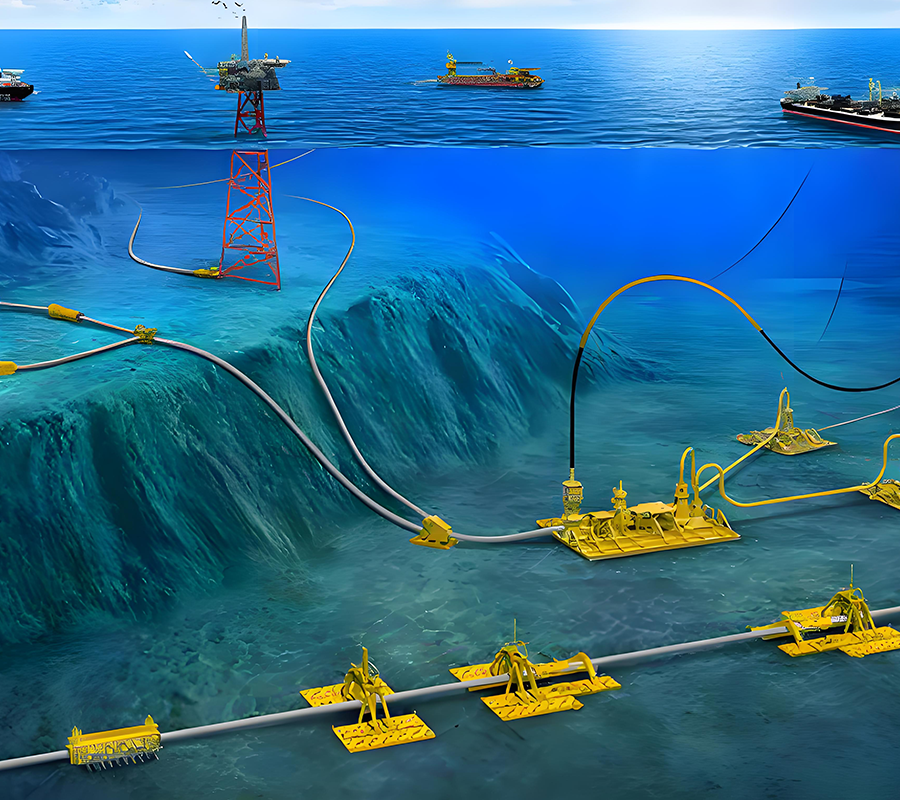

Offshore Deep Water Drilling System Seals

In order to solve the reliability problem of offshore drilling equipment sealing in high temperature, high pressure and high corrosive environment, we have developed a key sealing system for deepwater drilling equipment with independent intellectual property rights through 3 years of research and development, which covers the connection part of top drive, iron driller, turntable to riser assembly, and can run smoothly in the drilling system with a water depth of 12,500 feet, providing a strong guarantee for the stable and efficient operation of drilling equipment in the harsh deep-sea environment.

Operating Temperature: Up to 177°C/350°F,

Working pressure: 500psi~15000psi,

Working medium: contains 20% concentration H2S solution

Product diameter: 15mm~2000mm

Product Type: O-Ring, Y+O Ring, Combination Seal, Pan Plug Seal, Packing

Applicable equipment: diverters, risers, expansion joints, gravity joints, turntables, iron drillers, top drives and other drilling equipment, underwater equipment

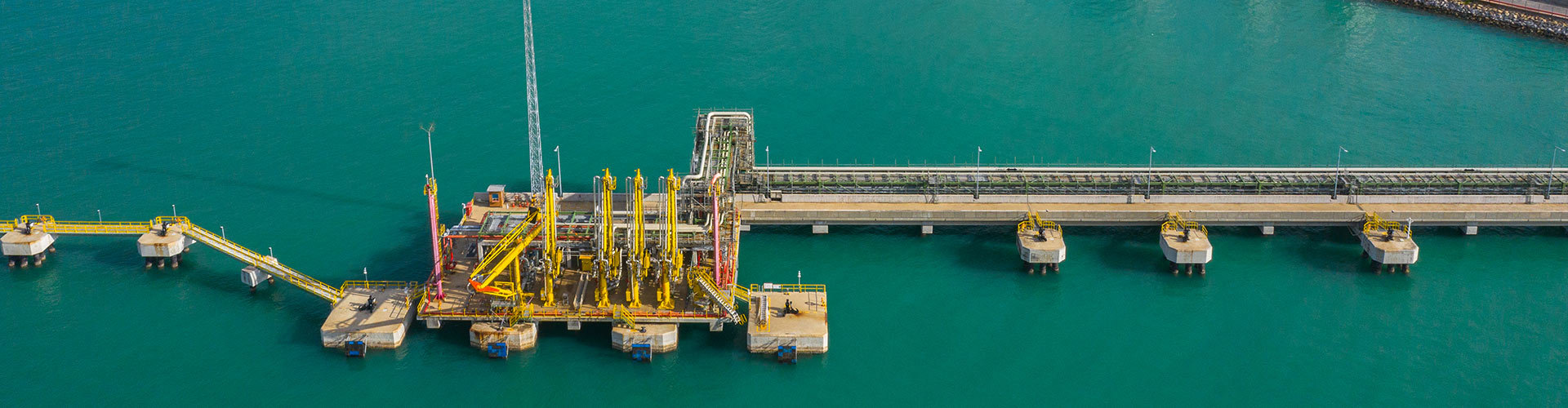

Offshore FPSO SPM Seals

Single-point mooring device is one of the core equipment of marine engineering, We has overcome the core design and construction technology of catenary single-point mooring device, and developed a catenary single-point mooring sealing system with independent intellectual property rights, which can realize the isolation of crude oil and seawater, and provide guarantee for the stable transportation of crude oil by FPSO.

Operating temperature: 50°C/122°F

Operating pressure: 290psi

Design life: 10 years, in line with API standard specifications

Product diameter: 15mm~2000mm

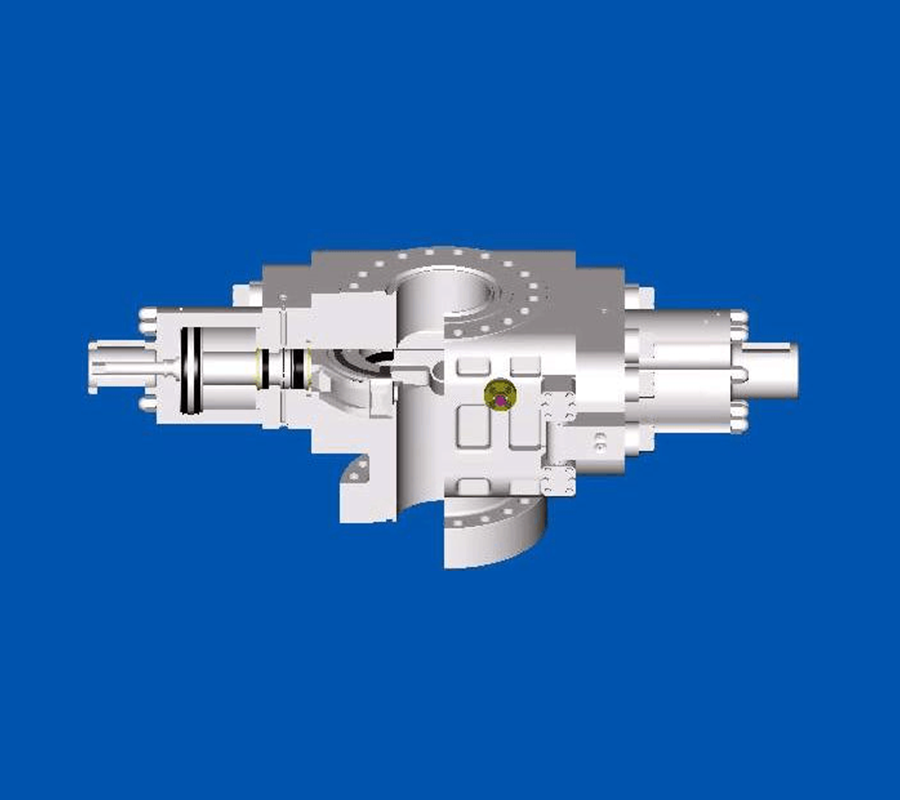

Land BOP Seals

We cooperate closely with well-known enterprises in the industry such as North China Rongsheng to provide high-quality BOP supporting sealing products, the main products cover end cover static sealing, cavity internal connection seals, side door side plate sealing rings, ram shaft sealing rings, and can provide special-shaped seal customization services according to needs.

Working pressure: 500psi-15000psi

Product diameter: 30mm~1300mm

Working medium: contains 20% concentration H2S solution

Product type: O-ring, Y-ring, rectangular ring, U-ring, etc

Applicable equipment: annular blowout preventer, ram blowout preventer

Pipeline Seals

We have been deeply engaged in the oil and gas pipeline industry for many years, providing customers with high-quality sealing products such as blind plate seals and combined gaskets, and can provide customized services for special-shaped seals according to customer needs. SINOMACH SEAL cooperates closely with well-known enterprises in the industry such as CNPC Pipeline and Sinopec, and its products are widely used in major petroleum and petrochemical pipelines, such as Lanyin Line, Mafang Distribution Station, Sino-Russian East Line, West Second Line Guangnan Branch Line, etc

02

Sealing solutions

Rongsheng Machinery Manufacture Ltd. of Huabei Oilfield

China Petrochemical Corporation

China National Petroleum Corporation

China National Offshore Oil Corporation

03

Supported operating conditions

Extreme Condition (FFKM)

The massive expansion of oil exploration and production needs to solve the problem of equipment sealing reliability in high-temperature, high-pressure and corrosive environments。For such extreme applications, we recommend the perfluoroelastomer material FFKM。

|

Type |

70B02 |

70B03 |

75B04 |

90B01 |

| Operating temperature/℃ |

300 |

230 |

280 |

290 |

| Hardness/Shore A |

70 |

70 |

75 |

90 |

| Tensile strength/Mpa |

20 |

18 |

18 |

16 |

| Elongation/% |

160 |

150 |

200 |

100 |

| 200℃*70h Compression/% |

10 |

19 |

30 |

8 |

| 260℃*70h Compression/%, |

/ |

/ |

40 |

15 |

| 300℃*70h Compression/% |

25 |

/ |

/ |

30 |

General working conditions

With the development of industrial technology, in order to meet the increasingly complex and diverse requirements of different industries and different working conditions, the branches and systems of sealing materials are becoming more and more perfect, and the physical and chemical properties are also constantly improving.

|

Type |

Temperature |

Medium |

Describe |

|||||||

|

Low /℃ |

High/℃ |

acid |

alkali |

oil |

water |

steam |

ozone |

corrosion |

||

|

FFKM |

-30 |

300 |

● |

● |

● |

● |

● |

● |

● |

Excellent media resistance, heat resistance, stability,excellent physical and mechanical properties |

|

FKM |

-15 |

200 |

● |

● |

● |

○ |

○ |

● |

○ |

On the basis of the original FKM formulation, the media resistance is improved |

|

HNBR |

-30 |

150 |

● |

● |

● |

○ |

○ |

● |

○ |

On the basis of the original HNBR formulation, the media resistance is improved |

|

NBR |

-50 |

100 |

● |

● |

● |

○ |

○ |

○ |

○ |

Most widely used rubber material, and its properties are relatively balanced |

|

EPDM |

-50 |

150 |

● |

● |

○ |

● |

● |

● |

● |

Excellent water resistance, but no resistance to oil-based liquids |

|

PU |

-30 |

80 |

○ |

● |

● |

○ |

○ |

○ |

○ |

Excellent mechanical properties, but the temperature grade is relatively low, and the acid resistance and hydrolysis resistance are poor |

● Supported ○ Unsupported

04

Seal Selection

Customization is supported, check our product center

For a full description, you can download our brochures: